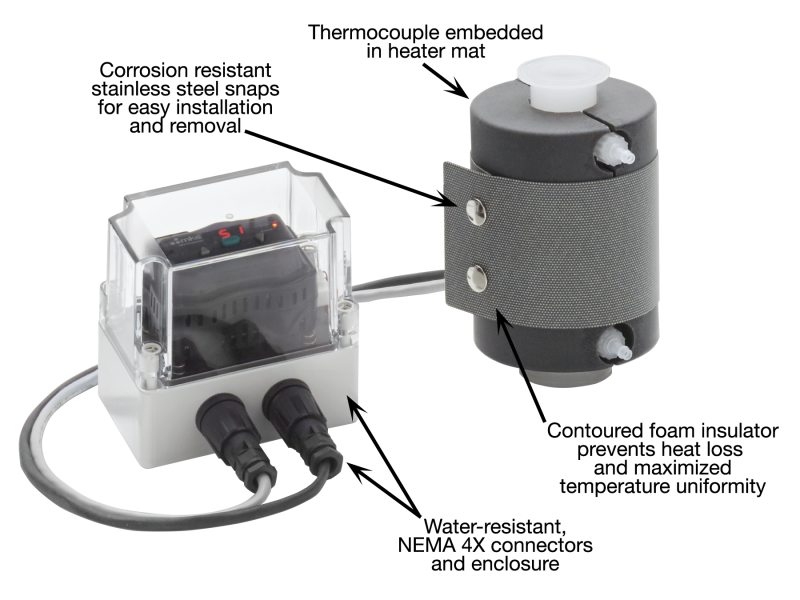

These 120 VAC filter housing heaters feature a temperature controller with an alphanumeric display and LED status indicators for local manual adjustments. The controller also includes Modbus RTU communications for remote control and monitoring. These filter housing heaters consist of molded silicone foam with a thermocouple embedded in the heater mat. The contoured design conforms to the housing body, preventing heat loss.

Features

Display and Communications Temperature Controller

The temperature controller manages all of the functions for the heater, including: temperature control, thermal safety, and operating status notification via three colored LEDs. The Display and Communications Module includes all the functionality of the Display Module, but adds Modbus RTU communications with an RS485 interface. This allows users to remotely adjust the operating parameters and monitor heater operating status. The temperature controller is housed inside a protective NEMA 4X-rated enclosure that is resistant to water and dust. The enclosure is also resistant to corrosion and damage from ice buildup.

Filter Heater Design

The Series 48 filter housing heaters consist of specially designed molded silicone foam for optimum performance and increased thermal uniformity with a thermocouple embedded in the heater mat for tight temperature control. The contoured design conforms to the housing body, preventing heat loss. Corrosion-resistant stainless steel snaps allow the heaters to be easily removed for filter cartridge replacement. External heater surfaces safe to touch.

Applications

Series 48 filter housing heaters are used in conjunction with sterile vent and process filter housings and are ideally suited for processes such as:

- Bioprocessing and Pharmaceutical Process Fluids

- Fermentation

- Product Recovery

- Water for Injection

- Filtration and Purification Processes

- Skidded Systems

- Tanks and Vessels

The NEMA-rated heaters allow for installation in the harshest of environments. The units can be mounted in any location where moisture is present, including clean-in-place (CIP) wash-down areas.

Resources

Literature

Series 48 Filter Housing Heaters(893.5 kB, PDF)

Manuals

Series 48 Filter Housing Heater Manual(884.4 kB, PDF)