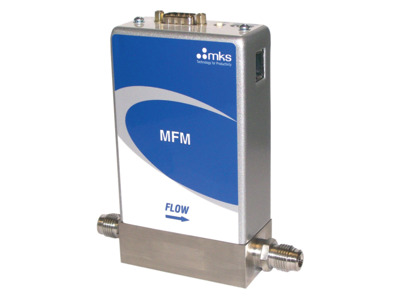

The G-Series GE50A digitally-controlled mass flow controller is available with either RS485, Profibus™, EtherCAT®, PROFINET, or DeviceNet™ I/O. The digital control electronics utilize the latest MKS control algorithms for fast and repeatable response to set point throughout the device control range. Typical response times are on the order of 500 milliseconds. Digital calibration yields 1% of set point accuracy on the calibration gas.

Features

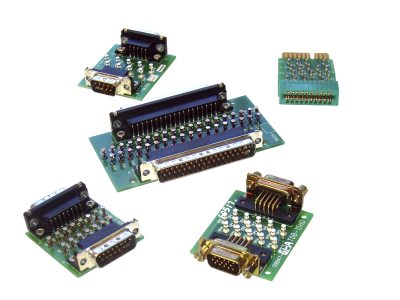

Wide Choice of Digital and Analog Interfaces

The GE50A digitally controlled MFC is available with either analog or digital I/O. The digital control electronics utilize the latest in MKS control algorithms providing fast and repeatable response to set point throughout the device control range. Typical response times are on the order of 500 milliseconds. The GE50A’s analog and digital I/O can easily be used to replace those same I/O types of the 1179A MFCs. All GE50As include Modbus as an available secondary I/O (excludes PROFINET® and EtherCAT®).

Standard 3 inch Footprint

The GE50A utilizes the standard 3-inch footprint most often used by MFCs in the 5 sccm to 50 slm flow rate range enabling its use without the need to modify existing gas line configurations.

All Metal Wetted Surfaces

The design of the GE50A incorporates a minimal use of elastomers. There is only one external elastomer seal and elastomer valve plug. Otherwise, all wetted surfaces are of metal. The GE50A comes standard with Viton® seals along with options for Buna, Neoprene®, EPMD or Kalrez® allowing for the device’s use with gases requiring one of these alternatives

Percent of Setpoint Accuracy

Included digital calibration yields 1% of set point accuracy with N2 calibration gas for 20 to 100% of the full scale flow range. Set point accuracy enables precise process control vs accuracy stated relative to full scale. For mass flow rates of 2 to 20% full scale the accuracy is ±0.2% of full scale.

Embedded User Interface

An embedded user interface provides the ability to easily change device range and user gas which reduces inventory requirements. You can also monitor MFC functionality and collect performance data in-situ.

Patented Thermal Sensor

A well proven, patented thermal sensor design provides exceptional zero stability. US Patent No 5461913.

Communication Options/Specifications

| Digital I/O | DeviceNet™ | RS485 | Profibus® | EtherCAT® | PROFINET® |

|---|---|---|---|---|---|

| Input Power Required | +11 to +25 VDC per (<2 watts) | +15 to +24 VDC (<2 watts) | +15 to +24 VDC (<2 watts) | +24 VDC (<3 watts) | +24 VDC (<3 watts) |

| Connector | 5 pin micro connector (power and comm.) | 9 pin Type D male (power and comm.) | 9 pin Type D male (power) 9 pin Type D female (comm.) |

2 x RJ-45 (comm.) male, M8 male, 5 pin (power) |

2 x RJ-45 (comm.) male, M8 male, 5 pin (power) |

| Data Rate Switch/Selection | 4 positions: 125, 250, 500K (Default) (programmable over network) |

No switch Set data rate via RS485 | No switch Set data rate via Profibus | No switch | No switch |

| Comm. Rate(s) | 125 Kbps; 250 Kbps; 500 Kbps | 9.6 Kbps; 19.2 Kbps 38.4 Kbps | 9.6 Kbps to 12 Mbps | 100 Mbps | 100 Mbps |

| MAC ID Switches/Addresses | 2 switches, 10 positions; 0,0 to 6,3 1 to 254 | Set address over RS485 Station Addresses 0,0 to 9,9 | 2 switches, 10 positions | 3 switches, 16 positions | N/A |

| Network Size | Up to 64 nodes | Up to 32 nodes | Up to 99 nodes | Up to 4095 nodes | N/A |

| Visual Indicators | LED Network (green/red) LED Module (green/red) |

LED Comm (yellow) LED Error (red) |

LED Comm (green/red) LED Error (green/red) |

LED Power (green) LED Run (green) LED Error (red) LED Comm (green) |

LED Maint (amber) LED BUS Fault (red) LED Ready (green) LED Sys Fault (red) |

| Compliance | CE | CE | CE | CE | CE |

Mass Flow Controller Repair, Calibration & Evaluation:

MKS Service Solutions provide customers access to MKS certified repairs, original design engineers, complete product testing with original specifications found at no other repair center in the world. Our services testing often leads to predicting potential future issues which leads to equipment longevity.

Accessories

Resources

Literature

GE50A Elastomer-sealed, Digital Mass Flow Controller(449.5 kB, PDF)

Other

Application Notes

Gas Delivery for Plasma Spray Coating Applications(320.8 kB, PDF) MFCs for Gas Control in Case Hardening Processes(246.3 kB, PDF) Sample Gas Codes for Mass Flow Controllers/Meters Gas Correction Factors for Thermal-based Mass Flow

Manuals

G and I Series Mass Flow Controller/Meter Manual(2.2 MB, PDF) G-Series Mass Flow Controller/Meter DeviceNet™ Supplement(112.5 kB, PDF) G-Series Mass Flow Controller/Meter RS485 Supplement(149.3 kB, PDF) G and I-Series Mass Flow Controller/Meter Profibus Manual Supplement(86.9 kB, PDF) G-Series Mass Flow Controller/Meter PROFINET Communications Supplement(1 MB, PDF) G-Series/I-Series MFC Modbus Register Map and Specification(502.9 kB, PDF) G-Series MFC Web Browser Tutorial(5.6 MB, PDF) G-Series Mass Flow Controller & Meter EtherCAT Manual Supplement(1.1 MB, PDF)

Drawings & CADs

Technical Notes

Device Description Files

GE50A Profibus GSD File (1480 compatible)(2.6 kB, GSD) GE50A Profibus GSD File (1179B compatible)(2.5 kB, GSD) GE50A EDS File(346.2 kB, EDS) GE50A ESI File(132 kB, XML)