MKS' LIQUOZON® VariO3 is a dissolved ozone gas delivery system providing high purity ozone in ultrapure water for Semiconductor and Electronic Thin Film applications like contaminant removal and surface conditioning via wet clean or rinsing methods. The high redox potential of ozone causes rapid conversion back to oxygen making it an environmentally friendly alternative to other chemical processes.

The VariO3 system has user controllable and configurable dissolved ozone concentration and flow rates, meeting specific requirements for a wide range of applications. The modular and versatile mechanical system interface makes it easy to integrate and service in today's equipment facilities and meets the latest safety and monitoring requirements.

Features

Leading Technology

- MKS proprietary contacting system allows >80% ozone mass transfer

- <5% concentration accuracy at constant flow rates typical

- Green idle modes reduce excess water usage

Process

- Wide operation window with tight process control

- Analog and digital bidirectional communication with remote control

- High purity ozone environment

Reliability & Maintenance

- High unit to unit reliability and repeatability

- Market proven components with long life-spans

- Easy installation and operation

Semiconductor Applications:

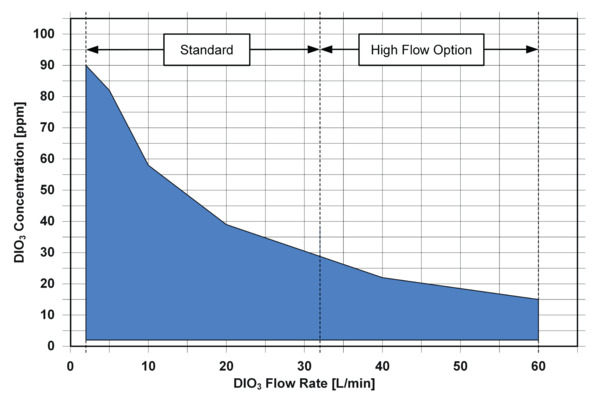

The LIQUOZON VariO3 platform hosts a number of models inside the same cabinet, covering a wide range of performance. The low concentration VariO3 delivers up to 90 ppm DI-O3 at rates of 2 liters/min and up to 15 ppm DI-O3 and flow rates of up to 60 liters/min (Figure 1).

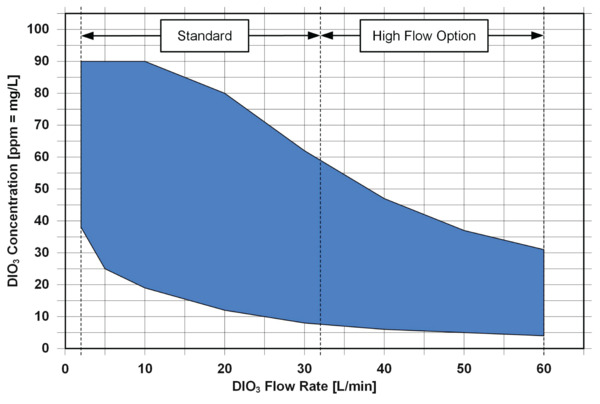

The standard version (Figure 2) delivers a maximum of 31 ppm DI-O3 at 60 liters/min while having a boosted mid-range performance. Both are ideally suited for single wafer cleans, oxide growth, and post CMP cleans as well as immersion applications.

Specified achievable dissolved ozone concentration in UPW for a system pressure of 2.5 barg, a cooling water temperature and UPW temperature of 20°C.

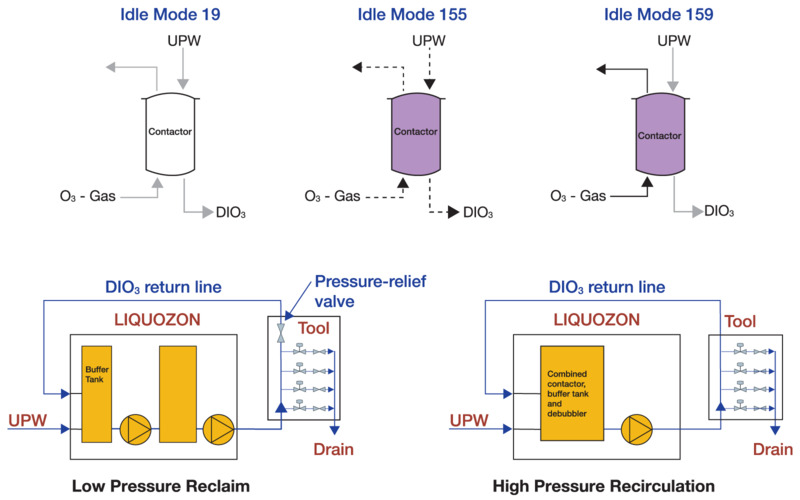

Water consumption is a serious concern for semiconductor fabs. Depending on the process step, ultra-pure water may be required to constantly stream resulting in significant waste of water. The LIQUOZON Ozonated Water Delivery System is equipped with multiple modes to improve water usage efficiency by lowering initial water consumption and reclaiming used process water. The LIQUOZON VariO3 supports Idle Modes 15, 155, and 159 as shown below.

Thin Film Applications:

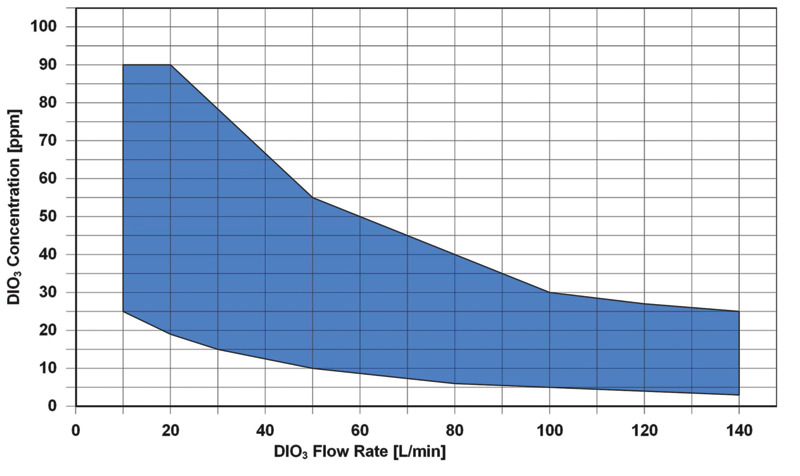

The LIQUOZON® VariO3 for Electronic Thin Film (also known as Flat Panel Display) system is designed for use with wet benches having cleaning applications requiring up to 140 L/min DI-O3 flow and ozone concentrations of 25 - 90 ppm (Figure 1). The LIQUOZON® VariO3 system uses closed-loop controls to maintain stable DI-O3 concentrations, even with varying DI-O3 demands. The built-in optional pump makes it ideally suited for fabs with low pressure UPW supply.

Facilities Requirements

O2: ≥ Grade 4 (purity ≥ 99.99%)

- Inlet Pressure: 4.5-7.6 barg (65-110 psig), at least higher 3 bar than system pressure

- Flow Rate: ≤ 15 slm, typical 9 slm, according to SEMI E12 (0°C/1.01325 bar)

Dopant Gas CO2: ≥ Grade 4.5 (purity ≥ 99.995%)

- Inlet Pressure: 5.0-7.6 barg (73-110 psig)

- Flow Rate: Typical 0.15-0.5 slm, depending on the configuration

Ultra-Pure Water (UPW)

- Half Life Time of O3 in UPW: >12 min @ 20°C, (which is standard in semiconductor fabs)

- UPW IN Pressure (full flow): 1-5 barg (14.5-73 psig) maximum, 0.8 bar higher than system pressure

- Temperature: 15-25°C (59-77°F), rated 20°C (68°F)

Cooling Water

- Quality: Demineralized, filtration ≤ 20 µm

- Temperature: 17-23°C (63-73°F), rated 20°C (68°F)

- Pressure: Maximum 5.0 barg (73 psig) differential pressure ≥ 3 bar

- Flow Rate: 3.0- >10.0 L/min (0.8- >2.6 gpm), depending on the configuration

Power: 3/PE~, 200-208 V ±10%, 50/60 Hz, 850-8000 W

Resources

Literature

LIQUOZON® VariO3 Dissolved Ozone Delivery System(310.6 kB, PDF) LIQUOZON® VariO3 Dissolved Ozone Delivery System for Electronic Thin Film Applications(2 MB, PDF)

Drawings & CADs

Application Notes

Ozone Data Conversion Tables(289.1 kB, PDF) Ozone Applications in the Semiconductor Industry(2.2 MB, PDF) Reduce Ultrapure Water UPW Usage Using MKS Reclaim Technology(1.5 MB, PDF)