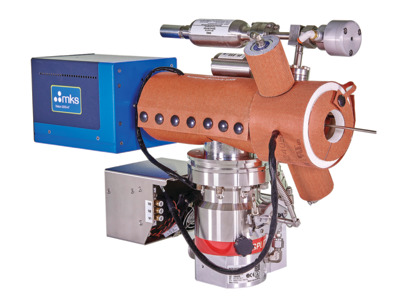

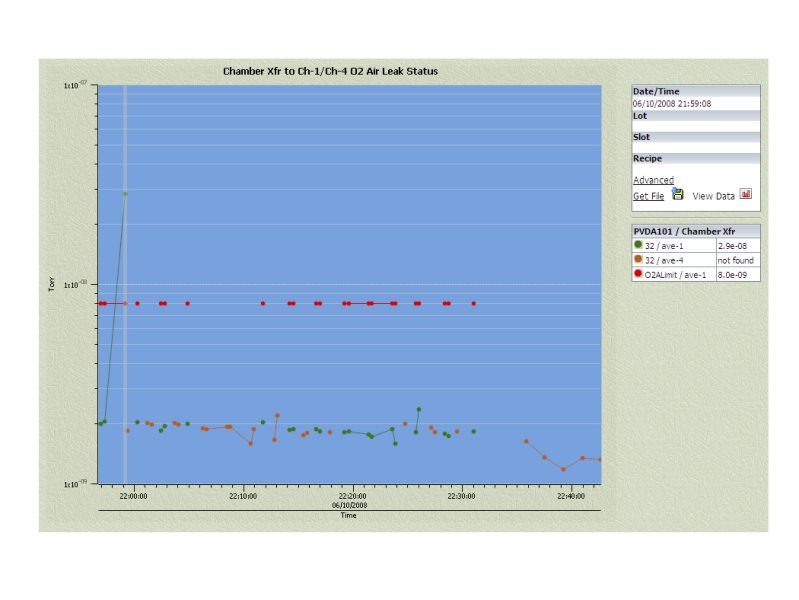

The Vision 2000-A Residual Gas Analyzer (RGA) improves process productivity and product quality by providing real-time trace level monitoring of various gas species, including precursors, reaction byproducts, and contaminants during ALD and CVD processes. It can monitor the chamber baseline for air leaks and background contamination levels. In-situ monitoring of ALD and CVD processes can help characterize and prevent damage to production equipment and wafer yield loss owing to precursor concentration change, chamber leak or contamination.

- Modular UniBloc inlet with all metal seals and field serviceable parts

- Temperature inlet up to 200°C (consult the factory for models up to 300°C)

- Direct coupling for a sample transfer tube See All Features

Features

"Smart Head" RGA Technology

The Vision 2000-A incorporates the Microvision 2 "smart head" RGA technology with a closed ion source and close-coupled inlet. This state of-the-art RGA technology is integrated with the Process Eye Professional control platform, a recipe based, user configurable software program. The combination of a closed ion source and automated inlet allows seamless monitoring of the complete ALD or CVD process cycle, from base vacuum to process pressures up to 760 Torr. By maximizing the ratio between gas signals and the gas background in the differentially pumped Vision 2000-A analyzer housing, the closed ion source enables sub-ppm-level detection for trace reaction byproducts and contaminants in the process gas. The closed ion source analyzer is manufactured from vacuum prepared stainless steel and high-density alumina ceramics and features independently replaceable twin filaments to provide built-in backup in the event of a filament failure. The standard system includes a double-filter analyzer to increase the sensitivity of high mass species (for ALD/CVD precursors with high molecular weight), improving contamination resistance and enhancing long-term stability.

Each Vision 2000-A system incorporates a Remote Vacuum Controller (RVC) that provides fail-safe protection for both the process tool and the RGA. It allows full operation and control of RGA system components (filaments, pumps, inlet valves, bakeout, etc.) from the system PC. Available in a compact, remotely mounted rack module, the RVC, is also the system power supply. The unit is easily mounted into any standard 19" tool rack for mounting on a process chamber or other compatible location. Thirty-three-foot (10 m) cables are included as standard so the RVC can be mounted at a convenient distance from the RGA sampling system on a process chamber (other lengths are available).

High Temperature Modular UniBloc™ Inlet

The Vision 2000-A modular UniBloc inlet is designed to operate at temperatures of up to 200°C for the whole sampling inlet with modular valves and flow elements. All external seals are metal. Many ALD and CVD precursors are liquid or solid at room temperature and may condense, leading to blockage of the gas sampling inlet if the sampling inlet and valve are not at the required temperature. A conformal heating jacket provides uniform temperature control of the whole inlet and valve to eliminate cold spots and prevent precursor condensation, minimizing deposition within the valve and maintaining mobility of sticky or polar gases through the inlet. The high temperature sampling inlet of the Vision 2000-A resists blockage and enhances the lifetime of the inlet during sampling of ALD or CVD precursors. If flow element or valve maintenance is required, the new modular design makes it a quick and cost-effective end-user operation, easily performed in the field.

The modular UniBloc is engineered to have minimal internal volume and surface area, reducing surface reactions and providing fast response to ALD process chemistries. Furthermore, a sample transfer tube can be connected directly onto the face of the modular UniBloc, giving a fast, coaxial flow path from the optimum point of the process equipment to the ion source. From its 1/8 inch internal compression ferrule connection, users can readily adapt to any choice of tube size and material. The exclusive fast response of the new modular UniBloc inlet manifold allows sampling at both background and process pressures through specific, selected orifices. When not sampling, the inlet valves close and the analyzer is automatically isolated from the process chamber. Optional purging of the inlet is available to flow inert gas through the mass spectrometer system while not sampling (purge gas does not flow to the process chamber). Such purging is active during bakeout, reducing initial startup time and residual background recovery time.

When sampling gases from >10 Torr, two-stage pressure reduction is provided using bypass pumping. For processes with maximum pressures <10 Torr, low-flow sampling through a single orifice is common, but with performance degradation in ALD applications. With the modular UniBloc inlet, a special configuration is available to draw supplemental sample flow to the inlet via bypass pumping, reducing both sample gas transfer lag and spreading of gas composition changes. In combination with a direct sample transfer tube, this optimizes pulse monitoring.

The inlet valve is operated by integrated electronics and controlled via recipes from Process Eye Professional. The required valve selection is made automatically by a gas independent pressure sensor in the modular UniBloc inlet which also provides a readout of the process chamber total pressure in the Process Eye Professional software.

ALD Ready Measurement

Common RGAs use a single filter mass analyzer with poor transmission (sensitivity) for high mass ions. For example, above mass 180 amu, transmission can be 10% of that at lower masses where detection limits are specified. Such RGAs have high mass detection limits that are 10x worse than specified for N2. The Vision 2000-A system uses double filters (with a pre-filter quadrupole), which significantly increases high mass transmission, thus enhancing the sensitivity of ions with high mass-to-charge ratio. This is extremely important for ALD/CVD processes that always use precursors with large molecular weight. The Vision 2000-A is capable of monitoring both low mass gas species, e.g. vacuum residual gas, reaction gas or by products, etc, as well as high mass precursors, and their fragment ions, with reduced loss of detection limit. In practice, this is often the difference in being able to monitor reaction species or not.

Vision 2000-A's improved electronics provide fast scanning and wide dynamic range of each scan of monitoring process gases and trace byproducts. In addition, the newly designed modular UniBloc inlet with minimized internal volume and surface area, when tailored to the process chamber configuration and process pressures, eliminates sampling gas delivery delays and lose of sampling fidelity. All these features make the Vision 2000-A RGA capable of responding to the short ALD pulse cycle with wide dynamic range for tracking dynamic gas chemistries.

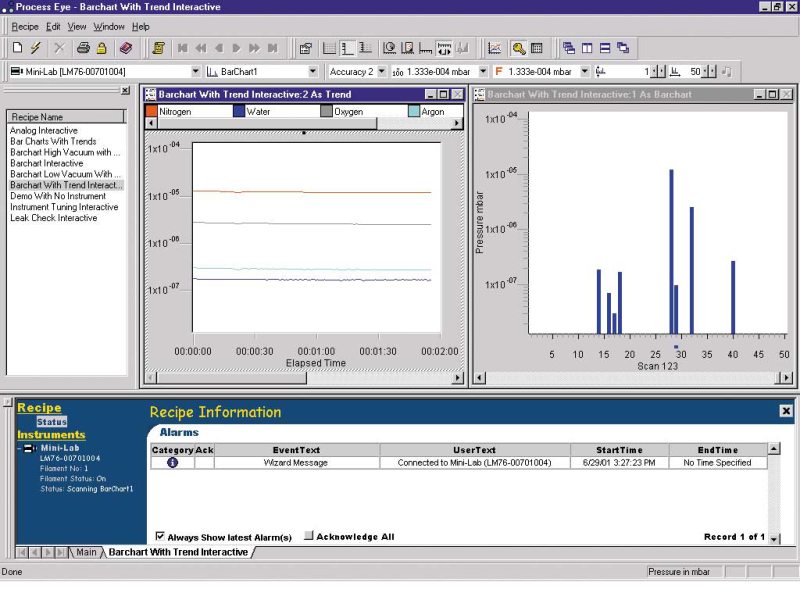

Vision 2000-A Process Eye Professional Control Platform

The Vision 2000-A analyzer uses Process Eye Professional, a highly flexible, modular application operating on 32- or 64-bit Windows 7, Server 2016 or Windows 10. Designed with a client/server structure, Process Eye Professional incorporates TCP/IP protocol for full network compatibility. Creating process recipes is made easy by the recipe wizard function which allows customized warnings and alarm levels to be triggered whenever the process exceeds preset levels. The Process Eye Professional recipes specify the way in which the Vision 2000-A acquires, displays and stores data. Other key parameters, such as ion source settings, can be set. This allows the user to optimize settings for each phase of the process independently. For example, ideal settings for baseline can be set up in the baseline recipe, ideal settings for process monitoring can be set in the process recipe, etc.

Process Eye Professional enhances the Vision 2000-A by providing:

- Automated and intelligent operation of MKS RGAs with fully customizable controls and alarms

- Recipes for automated calibration

- Flexible scanning

Bar Chart, Analog and Peak Jump scanning modes can be mixed and associated with data trend displays - Intelligent, user defined warnings and alarms

Can include a suggested diagnosis of the fault condition and recommended solution - Data displays in relevant units, such as Torr, mbar or Pa, in the process chamber

- Optional ability to read data from other sensors using analog inputs and external events by digital inputs

- Data buffer for quick on-line review of recent data

- Full storage of all data for subsequent review and analysis

TOOLweb® RGA

Building on the foundation of Process Eye Professional, the available TOOLweb RGA Platform and its process modules enable the Vision 2000-A to be used for ALD and CVD processes in a completely automated process environment, providing constant monitoring of tool activities with all sensor data being framed by wafer logistics before alarm models are applied. Full alarm and data reporting to the FAB host and FDC are available allowing real-time monitoring of chamber conditions and flagging of any process excursions from ideal behavior.

Resources

Literature

Vision 2000-A RGA for ALD & CVD(2.8 MB, PDF)

Drawings & CADs

Vision 2000-A & Vision 2000-A XD Dimensional Drawing(499.1 kB, PDF)