The 226B Differential Baratron® is a general-purpose differential capacitance manometer available in full-scale measurement ranges from 0.2 to 1000 Torr and can be configured with a wide variety of fittings, input/output signals, and electrical connectors. It is mounted in a rugged industrial-grade housing that minimizes external RF/EM interference on the electronics and when properly configured, is completely "drop-in" compatible with earlier Baratron® differential manometers.

Features

Baratron® Capacitance Manometer Technology

Capacitance manometers are electro-mechanical gauges that can measure both pressure and vacuum. The capacitance gauge translates a pressure-modulated movement in a thin diaphragm into an electrical signal proportional to the pressure. The pressure sensor is the thin diaphragm that is exposed to the pressure or vacuum being measured via the inlet tube. An electrode is mounted in the reference cavity behind the diaphragm. Pressure differences between the process and the reference cavity deflect the diaphragm slightly, changing the distance between it and the electrode. Variations in this distance produce variations in the capacitance between the diaphragm and the electrode creating an electrical signal that is proportional to the pressure change. Since differences in the capacitance signal are produced by physical changes within the manometer and not by changes in the gas properties, pressure measurements by the capacitance manometer are independent of the composition of the gas being measured.

Differential Pressure Measurement

Differential capacitance manometers can be connected to any pressure or vacuum source for use as the reference pressure. These manometers read the difference in pressure between the inlet tube and the reference cavity at the backside of the electrode. Differential pressure transducers can be used to measure either the true differential pressure or vacuum between two locations, or the reference side of the product can be left open to provide a true reference to local atmospheric pressure. Applications include air and gas flow measurements for filters and analytical systems, downstream pressure control in thin film processing systems, and automated leak testing systems.

Inconel® Nickel Alloy Construction

The patented capacitance sensor is built entirely from Inconel® nickel alloys on its measurement side, which offers superior corrosion resistance over long periods of time. Inconel® construction also offers high overpressure tolerances that reduce errors due to line pressure spikes, and high burst pressure ratings that contribute to overall system safety.

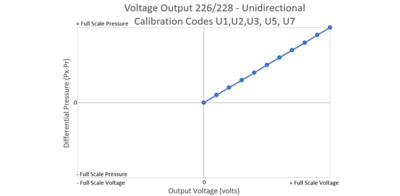

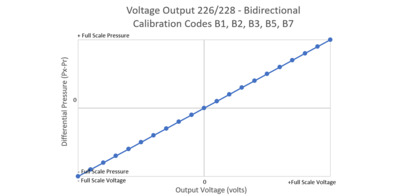

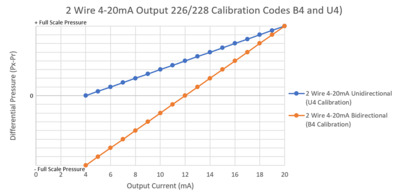

Wide Variety of Proportional Analog Outputs

226 & 228 differential capacitance manometers provide a high-level analog output signal that is linear with pressure. It can operate on either ±15VDC or +24VDC input voltage, and it offers four different analog output signals (0-10V, 0-5V, 0-1V, and 4-20 mA) for use in nearly any control or data acquisition system. The sensor and electronics are mounted in a rugged industrial-grade housing that has high immunity and isolation from RF and EM interference.

Twelve Different Fitting Types

These Baratron® differential capacitance manometers can be equipped with any of twelve (12) different fittings on either the measurement or reference sides, including common industrial and semiconductor-industry standards like VCR®, NW-KF, VCO®, and NPT.

Accessories

Compatible Cables

Power Supplies and Displays

Resources

Literature

226B Differential Baratron® Capacitance Manometer(2.1 MB, PDF)

Application Notes

Pressure-based Leak Testing(201.7 kB, PDF)

Manuals

MKS 226B & 228A Differential Transducers Manual(609.2 kB, PDF) 226 Differential Capacitance Manometer Pin-outs(31.7 kB, PDF)