The 631F 1-1000 Torr, Heated (150 or 200°C) Absolute Baratron® Capacitance Manometer, operating at very high internal temperatures, minimizes the deposition of process byproducts within the sensor by nearly eliminating output drift caused by contamination. Its available operating temperatures are 150°C or 200°C, permitting use in the most demanding vacuum processes in semiconductor manufacturing such as metal etching and nitride film chemical vapor deposition (CVD).

Features

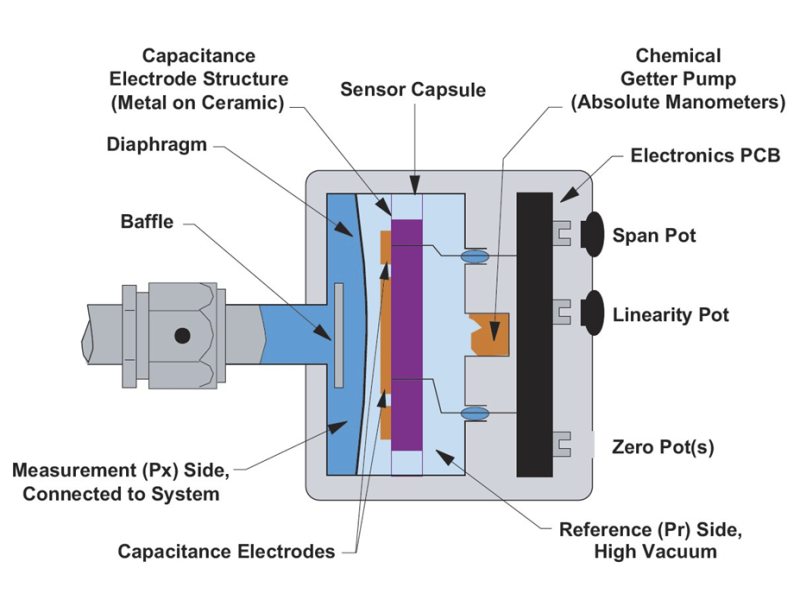

Baratron® Capacitance Manometer Technology

Capacitance manometers are electro-mechanical gauges that can measure both pressure and vacuum. The capacitance gauge translates a pressure-modulated movement in a thin diaphragm into an electrical signal proportional to the pressure. The pressure sensor is the thin diaphragm that is exposed to the pressure or vacuum being measured via the inlet tube. An electrode is mounted in the reference cavity behind the diaphragm. Pressure differences between the process and the reference cavity deflect the diaphragm slightly, changing the distance between it and the electrode. Variations in this distance produce variations in the capacitance between the diaphragm and the electrode creating an electrical signal that is proportional to the pressure change. Since differences in the capacitance signal are produced by physical changes within the manometer and not by changes in the gas properties, pressure measurements by the capacitance manometer are independent of the composition of the gas being measured.

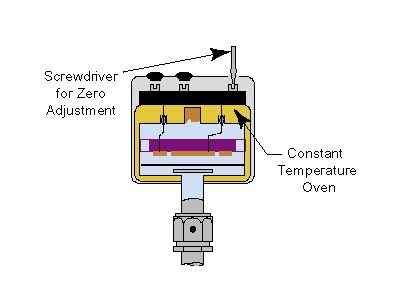

Internally Heated to 150°C or 200°C

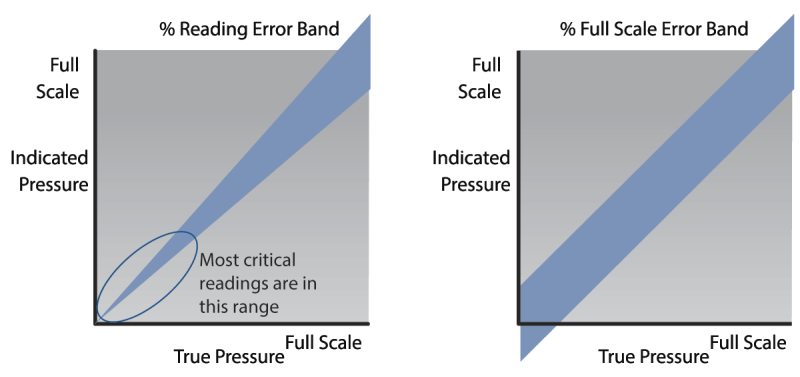

These capacitance manometers are temperature controlled to 150°C or 200°C for improved accuracy. Unheated sensors are exposed to ambient temperature variations which can degrade the sensor accuracy. These devices have the sensor enclosed in a volume that is maintained at a constant temperature above ambient. This solution improves the manometer’s accuracy and repeatability and lowers instrument drift by reducing or eliminating process contamination within the manometer permitting use in the most demanding vacuum processes in semiconductor manufacturing, such as metal etching and nitride film chemical vapor deposition (CVD).

Absolute Pressure Measurement

These Baratron® pressure transducers are referenced to vacuum for absolute pressure measurement. Applications include: vacuum furnaces, freeze-drying of fruits and vegetables, gas lasers, automotive component testing, bottle coatings, and vacuum distillation.

Inconel® and Incoloy® Construction Wetted Surfaces

These pressure transducers feature Inconel® and Incoloy® nickel alloy construction of the pressure sensor allowing it to operate without damage in virtually any chemical environment, including halogens, deionized water and steam, and ozone. The sensor is fully welded with no intermediate brazing or joining materials.

0 to 10 VDC Proportional Analog Output

These Baratron® capacitance manometers feature a high-level 0-10 VDC analog output signal that is linear with pressure. This analog output can be interfaced with an MKS pressure controller, an MKS power supply/display instrument, or any instrument that meets these requirements.

Two Adjustable Process Trip Point Relays

An internally-mounted set of two (2) UL-approved solid-state trip relays for pressure and one (1) UL-approved electromechanical relay for heater failure is also available, allowing the manometer to control external equipment or components. The pressure trip relays may be adjusted from 0.5% to 100% of full scale range by the user independently at atmospheric pressure, eliminating the need for vacuum pumps during setpoint adjustment. Relay capacity is 0.20 amps @ 30 VDC compling with UL1577 requirements.

15-pin Type "D" Pin-Outs with Relay Option

| Pin | Description |

|---|---|

| 1 | Trip Point A Relay N/O |

| 2 | Pressure Output |

| 3 | Trip Point A Relay Common |

| 4 | Trip Point A Relay N/C |

| 5 | Power Return |

| 6 | -15 VDC |

| 7 | +15 VDC |

| 8 | Trip Point B Relay N/O |

| 9 | Trip Point B Relay Common |

| 10 | Trip Point B Relay N/C |

| 11 | Heater Alarm Relay Common |

| 12 | Pressure Output Return |

| 13 | Heater Alarm Relay Open (when energized) |

| 15 | Heater Alarm Relay Closed (when energized) |

| 15 | Chassis Ground |

Accessories

Compatible Cables

Power Supplies and Displays

Resources

Literature

631F Heated (150°C or 200°C) Absolute Baratron® Capacitance Manometer(2 MB, PDF) Analog 600 Series Absolute Baratron® Capacitance Manometer Selection Guide(2.9 MB, PDF)

Manuals

MKS 631F High Temperature Transducer Manual(848.8 kB, PDF) 631 Capacitance Manometer Pin-outs(27.2 kB, PDF)