The AA01A Baratron® capacitance manometer is a high-performance, unheated, absolute pressure transducer developed specifically for use in vacuum and pressure measurement applications where accuracy and repeatability are crucial to process success. They use state-of-the-art digital architecture throughout to produce the highest possible long-term performance and reliability.

Features

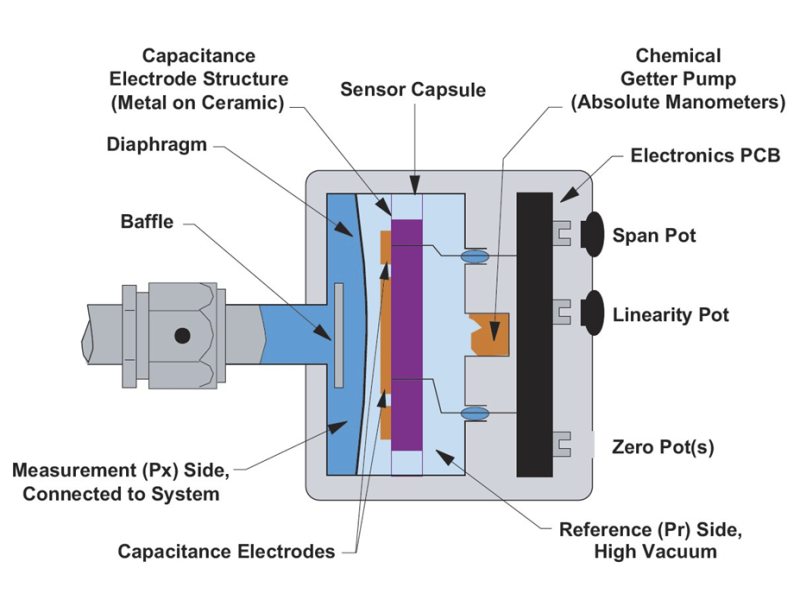

Baratron® Capacitance Manometer Technology

Capacitance manometers are electro-mechanical gauges that can measure both pressure and vacuum. The capacitance gauge translates a pressure-modulated movement in a thin diaphragm into an electrical signal proportional to the pressure. The pressure sensor is the thin diaphragm that is exposed to the pressure or vacuum being measured via the inlet tube. An electrode is mounted in the reference cavity behind the diaphragm. Pressure differences between the process and the reference cavity deflect the diaphragm slightly, changing the distance between it and the electrode. Variations in this distance produce variations in the capacitance between the diaphragm and the electrode creating an electrical signal that is proportional to the pressure change. Since differences in the capacitance signal are produced by physical changes within the manometer and not by changes in the gas properties, pressure measurements by the capacitance manometer are independent of the composition of the gas being measured.

Absolute Pressure Measurement

These Baratron® pressure transducers are referenced to vacuum for absolute pressure measurement. Applications include: vacuum furnaces, freeze-drying of fruits and vegetables, gas lasers, automotive component testing, bottle coatings, and vacuum distillation.

Inconel® and Incoloy® Construction

These pressure transducers feature Inconel® and Incoloy® nickel alloy construction of the pressure sensor allowing it to operate without damage in virtually any chemical environment, including halogens, deionized water and steam, and ozone. The sensor is fully welded with no intermediate brazing or joining materials.

Accessories

Power Supplies and Displays

Resources

Literature

AA01A Baratron® Absolute Capacitance Manometer Datasheet(266.5 kB, PDF)

Drawings & CADs

AA01A Baratron® Capacitance Manometer Dimensional Drawing(222.4 kB, PDF)